Description

Heat Shrink Solder Splice Sleeve Crimpless Butt Connectors

Our solder sleeves are primarily used to attach a ground wire (lead) to the shielding braid of a shielded cable by means of a shrinkable tubing assembly having an integral solder preform. Heat shrink solder splices are also used to splice two or more conductors together in a parallel configuration.

Features:

Glue Color & AWG & Length

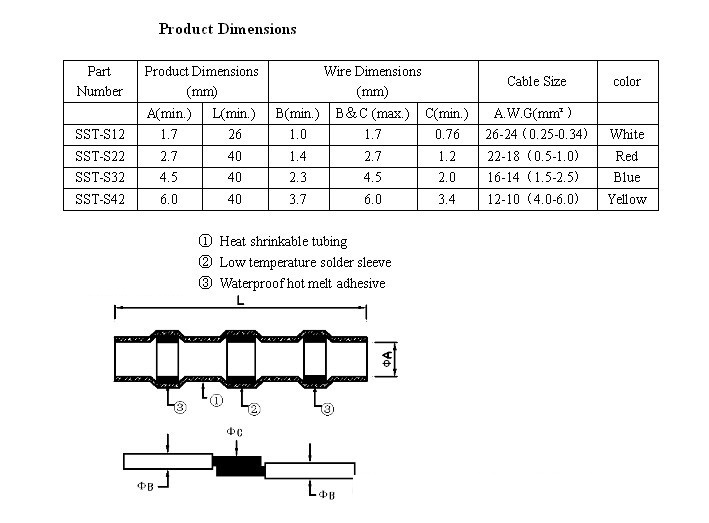

Glue Color: White Diameter: 1.7mm AWG: 26-24 Length: 26mm

Glue Color: Red Diameter: 2.7mm AWG: 22-18 Length: 40mm

Glue Color: Blue Diameter: 4.5mm AWG: 16-14 Length: 40mm

Glue Color: Yellow Diameter: 6.0mm AWG: 12 -10 Length: 40mm

- Different sizes and pack quantities available, can be used in marine, automotive and aviation.

Transparent Polyolefin Heat Shrink Tubing, Solder, and Adhesive Glue Ring.

Operating Temperature: -55°C to 125°C

One Step soldered, sealed and insulated butt connector - Material: Transparent Modified Polyolefin, Glue Ring, Solder Ring

Operating Temperature: -55°C-125°C

Fully Recovered Temp: 130°C

Temp of Solder Starting Melt: 125°C

Temp of Full Solder Melt: 150°C

Voltage Resistance: >600V

This is the easiest way to make soldered splice in your wiring. It is our favorite way to extend the wires on stepper motors.

This part combines a low temperature solder ring inside a piece of clear heat shrink tubing. It also has rings of hot melt glue at each end. You strip each wire, insert one from each end and cross the stripped ends inside the solder ring. You then heat the tubing with a heat gun. The solder and glue melts and the tubing shrinks. You get a reliable, insulated, waterproof and soldered connection in one operation.

It is also great when you need to fan out one wire to several wires. This often happens when you have one ground terminal, but four wires coming to it. Place the four wires in one end and one in the other end.

Solder splice heatshrink tubes allow you to quickly join two cables thanks to the small section of solder in the middle of the tube. Simply slide a tube over the join in two cables and heat as you would any other shrink tube. As the tube shrinks the solder melts to electrically connect the wires resulting in a join which is reliable and well insulated. Solder Splice terminator incorporating heatshrink and low melt solder with protection glands.

Used to make the perfect termination when connecting wires without crimping, Solder Splice Sleeve use 3 materials (solder, heat shrink, glue adhesive) to provide maximum pull-out strength, excellent conductivity and helps prevent corrosion.

Easy to install with just the use of a heat gun (must have enough heat to melt the solder), simply overlap the exposed ends of the wires and center the solder preform of the shield solder sleeve over the center conductors.

Now heat the solder preform until it melts onto the center conductor. Then heat the ends of the termination sleeve for a water tight seal.